-

Recent Posts

- Nema Enclosures Mfg. awarded ISO 9001:2015 re-certification as a Seal of Quality Standard

- NEMA 3RX Rating Now Offered

- NEMA ENCLOSURES MFG. RECEIVES ISO 9001:2015 CERTIFICATION

- Learn about our ATEX & IECEx Ex e Value Added Features and Accessories

- Motor Control Center (MCC) Drop-Over Custom Enclosures

Archives

- May 2021

- February 2021

- July 2018

- October 2017

- September 2017

- April 2017

- January 2017

- December 2016

- March 2016

- February 2016

- October 2015

- August 2015

- July 2015

- May 2015

- October 2014

- August 2014

- June 2014

- April 2014

- March 2014

- February 2014

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- February 2013

- January 2013

- December 2012

- November 2012

- October 2012

- September 2012

- March 2012

- February 2012

- August 2011

- May 2011

Motor Control Center (MCC) Drop-Over Custom Enclosures

What is an MCC drop-over enclosure and why use one?

An MCC Drop-over enclosure is an enclosure that is simply picked up and placed over your MCC to provide protection against environmental hazards.

MCC stands for Motor Control Center, which combines individual motor controllers into one large center with a common power bus. These are common on factory floors, water-treatment plants, chemical plants, etc.

Why use a drop-over enclosure? If you are planning to expand or don’t have enough room at your current facilities, or you just need environmental protection. They are also cost effective with very low installation time.

Follow us in our step-by-step process of creating your custom drop-over enclosure for your MCC.

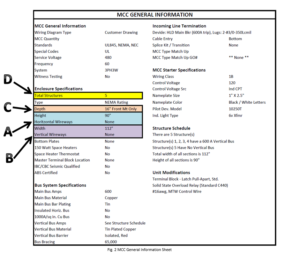

We can manufacture custom drop-over enclosures to the exact specifications you need for your MCC. Here is what we need from you:

- Your MCC General Information

- Environmental Factors & NEMA Rating

- Structure Requirements & Custom Features

1. MCC General Information

Based on your MCC general information, we will determine the following:

- Enclosure Height

- Enclosure Width

- Enclosure Depth

- Enclosure Door Configuration

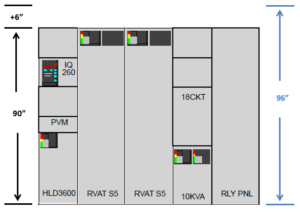

Determining Enclosure Height

To determine the height of the enclosure, we take into account:

- MCC Height

- Horizontal Wireway placed on top or bottom of MCC

Our standard is to add 6” to the MCC’s height to determine enclosure’s height.

We also consider if there will be a horizontal wireway on top or bottom of the MCC. Horizontal wireways are used for continuous dedicated wire and cable locations. If there is a wireway, we will add the height for a total MCC height.

In our MCC example below, the height is 90” with no horizontal wireway.

Therefore, the enclosure height will be 96”.

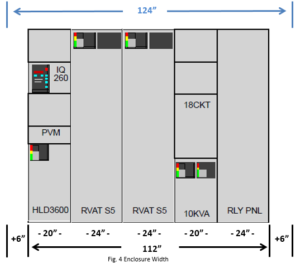

Determining Enclosure Width

To determine the width of the enclosure, we take into account:

- MCC Width

- Vertical Wireway placed on either side of the MCC

Our standard is to add 6” to both sides of the MCC for the enclosure’s width.

We also consider if there will be a horizontal wireway on top or bottom of the MCC. Vertical wireways are used for continuous dedicated wire and cable locations. If there is a wireway, we will add the length for a total MCC width.

In our MCC example below, the width is 112” with no horizontal wireway.

Therefore, the enclosure width will be 124”.

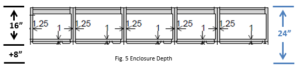

Determining Enclosure Depth

Our standard in determining the depth of the enclosure is to add 8” to the MCC’s overall depth.

In our example, the overall depth of the MCC is 16” therefore the enclosure depth will be 24”.

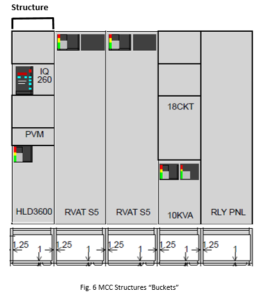

Determining Door Configuration

The next step is to determine the configuration of the enclosure doors for ease of access. We take into account the number of structures (commonly referred to as “buckets”), the enclosure width, and the MCC location, i.e. is it in an open area indoors or outdoors, or at a production facility with space limitations.

For smaller MCC’s that are not too wide and only require a NEMA 3R/12 rating, overlapping doors can be installed with no center-post.

For wide MCC’s require NEMA 4X rating, non-overlapping doors with center posts are used to keep the enclosure structurally sound and will allow for multiple access points to the structures.

In our example, the MCC has 5 total structures, the enclosure width is 124”, and it is located outside with no space constrictions. A NEMA 3R rating is required and so the determined door configuration is two sets of overlapping doors.

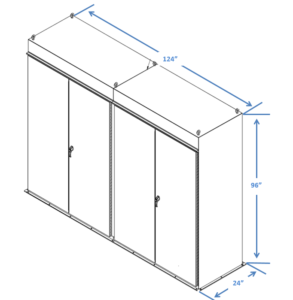

Based on all of the information gathered from the MCC General Information Sheet, the overall dimensions are:

- 96” High

- 124” Wide

- 24” Deep

2. Environmental Factors & NEMA Rating

An important factor to take into account is where the MCC is located which will allow for determining the material and NEMA rating of the drop-over.

If the location of the MCC is in a highly corrosive environment, we recommend either 304 or 316 stainless steel. In our example enclosure, we are using 304 Stainless Steel as the MCC is located outside a factory plant.

For less harsh environments, where only rain, dust, and wind are an issue, carbon steel is acceptable.

Here are the recommended ratings based on environmental factors:

Standard type for indoor use with no harsh or varying conditions. Enclosure will be gasketed.

May be used for outdoor use to protect against rain and sleet. Enclosure will be gasketed with overlapping doors.

May be used for indoor use to protect against dust, airborne matter, and dripping liquids. Enclosure will be gasketed around all doors, door cutouts, cover plates, side, top, and back sheets.

May be used for outdoor use to protect against falling dirt and windblown dust. Provides a degree of protection against ingress of water such as rain, sleet, snow, splashing water, and hose-directed water.

May be used for outdoor use to protect against falling dirt and windblown dust. Provides a degree of protection against ingress of water such as rain, sleet, snow, splashing water, and hose-directed water. Provides protection against corrosion and undamaged by external formation of ice.

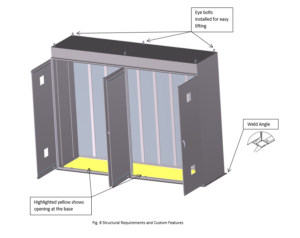

3. Structure Requirements & Custom Features

Now that we have the basic design configured, we can look into the overall structure requirements and additional custom features we offer.

Our standard design includes 2” x 2” x ¼” stainless steel weld angle to the bottom opening of the enclosure.

Drop Over enclosures are open on the bottom with eye bolts installed on top to allow it to be easily picked up and placed over the MCC.

Additional Custom Features:

Windows: Allow for visual inspection without opening the doors and minimizes personnel entry to the enclosure

Thru-holes: Provided in a steel channel at the base to securely bolt the enclosure to a concrete pad

Locking Mechanisms: Assist in preventing accidental exposure to energized parts and provides extra security

Powder-coating: Our enclosures undergo a multi-step cleaning and powder coat process resulting in uniform-thickness and powder coverage (further protects carbon steel drop-over). We can also powder coat stainless steel, aluminum, and galvanized steel. This process is maintained and controlled by ISO 9001 quality standards.

Louvers: Allow for air flow inside of the drop-over and keeps out rain if enclosure is located outside

Gland plates: Allow for easy wire installation and access

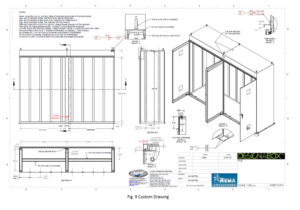

Now that we have the enclosure height, width, and depth as well as the door configuration and added features, our drafters will create a custom drawing of the enclosure.

The drawings are sent directly for your revisions and approval.

After any revisions have been incorporated into our submittal drawings and final customer approval on our submittal drawings has been received, we then proceed to release your custom drop-over enclosure to production and manufacturing can begin.

We have now built your custom drop-over enclosure to house your MCC without any additional and unnecessary features or space if you were to purchase a standard size. Here is our final product before it is ready to be shipped and installed at its final location.

Finally, your custom drop-over enclosure may be installed.

See below for photos of our customer installation.

Here at Nema we are innovative and we’ll work with you to deliver exactly what you need.

We know using drop-over enclosures to house MCCs is an ideal economical solution for solving space limitations or making plant expansions more affordable, and we are excited to work with you on your next project.

This entry was posted in custom enclosures, enclosures and tagged custom enclosure, drop over enclosure, mcc drop over, mcc enclosure, motor control center enclosure, what is an mcc enclosure. Bookmark the permalink.