Anodized Aluminum Enclosures

Nema Enclosures manufactures a variety of high-quality custom and standard NEMA-rated anodized aluminum enclosures. The enclosure anodizing process creates an oxide film and makes it more scratch-resistant. It changes the appearance of the metal to nearly any color from red to black or even clear. Anodizing ensures your enclosure has a durable and beautiful finish. It can also provide an extra layer of corrosion resistance to aluminum enclosures. The two most common types of anodizing include:

- Sulfuric acid anodizing, also known as Type II Anodizing, is the most widely used anodized coating solution because of its environmentally friendly composition and less expensive pricing. This film, or coating, can be dyed in any color. Hard coating anodizing, known as Type III Anodizing, is a great metal finish for aluminum. This outer coating allows the part to be protected from corrosion and deterioration.

- Hard coat anodizing enhances the properties of aluminum. It improves electrical resistance, hardness, and thermal conductivity.

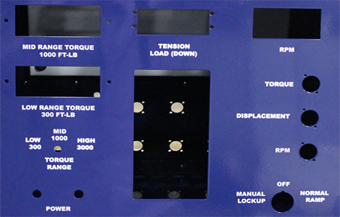

Common enclosure anodizing colors include; Black, Gold, Green, Blue, Red, Bronze, and Clear. Special colors are available upon request.

Nema Enclosures fabricates quality UL-rated electrical and instrument enclosures to your exact specifications and that meet your lead times. We believe that thinking about your electrical enclosure needs while you’re configuring what goes into it will save you time, money, and frustration. Contact us today to learn how we can expedite custom anodized aluminum enclosures and produce cost-effective safety-rated standard enclosures to protect you and your equipment.