-

Recent Posts

- Nema Enclosures Mfg. awarded ISO 9001:2015 re-certification as a Seal of Quality Standard

- NEMA 3RX Rating Now Offered

- NEMA ENCLOSURES MFG. RECEIVES ISO 9001:2015 CERTIFICATION

- Learn about our ATEX & IECEx Ex e Value Added Features and Accessories

- Motor Control Center (MCC) Drop-Over Custom Enclosures

Archives

- May 2021

- February 2021

- July 2018

- October 2017

- September 2017

- April 2017

- January 2017

- December 2016

- March 2016

- February 2016

- October 2015

- August 2015

- July 2015

- May 2015

- October 2014

- August 2014

- June 2014

- April 2014

- March 2014

- February 2014

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- February 2013

- January 2013

- December 2012

- November 2012

- October 2012

- September 2012

- March 2012

- February 2012

- August 2011

- May 2011

Nema Enclosures Mfg. awarded ISO 9001:2015 re-certification as a Seal of Quality Standard

Nema Enclosures Mfg. is proud to announce our successful re-certification to the ISO 9001:2015 standard and have been recommended for continued certification for the next 3 years. As this was our recertification audit it was a more in-depth audit than the normal surveillance audits and it went extremely well. Quality management is a never-ending journey of continuous improvement, a journey that Nema Enclosures has fully embraced as we look to maintain a high level of quality, responsive customer service, and overall performance and efficiency.

ISO 9001 remains one of the most widely used quality management standards, a symbol that is globally recognized and valued. The 2015 revision of ISO 9001 requires greater involvement of senior management, more focus on stakeholder (not just customer) expectations, and a greater assessment of risks and opportunities.

Maintaining and Improving our quality processes

Maintaining our ISO 9001:2015 certification demonstrates our ongoing commitment to maintain a high level of quality and responsive customer service, improve overall performance and efficiency, and to provide a firm foundation in our approach to continual improvement initiatives for technology, design, and processes and procedures. Our certification gives our customers the assurance that our processes consistently provide products that meet their needs and expectations, as well as any applicable statutory and regulatory requirements. The role of the internal quality auditor has also changed, it is no longer enough to check procedural conformance, auditors now need to be able to audit processes with an emphasis on risk. Internal auditors play a key role in the development and improvement of our working practices across our business. We have an amazing team of internal auditors at Nema Enclosures Mfg., qualified to a highly interactive certified training program on the most important attributes of a modern and effective quality management system. For our employees, our QMS provides them direct access to the company processes and procedures. It also promotes a positive culture of continuous improvement and training, so that employees gain a better understanding of quality, customer focus, and how their role fits within the business.

To achieve the intended objectives, a QMS must be maintained on a regular basis to remain compliant with the standard and relevant to operations. To verify ongoing compliance, the certifying body or registrar conducts periodic audits within 3 years to ensure the system is being maintained and adheres to the organization’s processes. we are proud to have the certification in place and our commitment to an integrated Quality policy. It helps to promote a positive culture to drive our success in continuously improving our training and management systems. It is an integral part of our business strategy and performance.

For some companies, the journey to continuously improve and maintain compliance can be an even more difficult journey than the initial certification. Nema Enclosures, however, welcomes the challenge of external audits, as these ensure that we keep our systems, equipment/technology, and processes up-to-date and maintain the high levels of performance that might otherwise degrade over time into comfortability.

We at Nema Enclosures would like to take this opportunity to extend our thanks and appreciation to all our employees for their efforts in once again achieving this goal. To our customers and our suppliers, thank you for your continued loyalty and commitment to our objectives. We recognize that while this achievement is yet another important milestone for Nema Enclosures, our journey is never done. We look forward to the process and product improvements we have planned, as well as our continued dedication and focus on quality and exceeding your requirements.

If you would like to know more about our products, or if you have questions about our Quality Management System or re-certification, please contact us at customerservice@nemaenclosures.com.

About DNV GL – Business Assurance

DNV GL – Business Assurance is part of the DNV GL Group, a world-leading certification body helping businesses assure the performance of their organizations, products, people, facilities, and supply chains through certification, verification, assessment, and training services.

For more information about DNV GL – Business Assurance, visit www.dnvglcert.com.

Posted in enclosures

Comments Off on Nema Enclosures Mfg. awarded ISO 9001:2015 re-certification as a Seal of Quality Standard

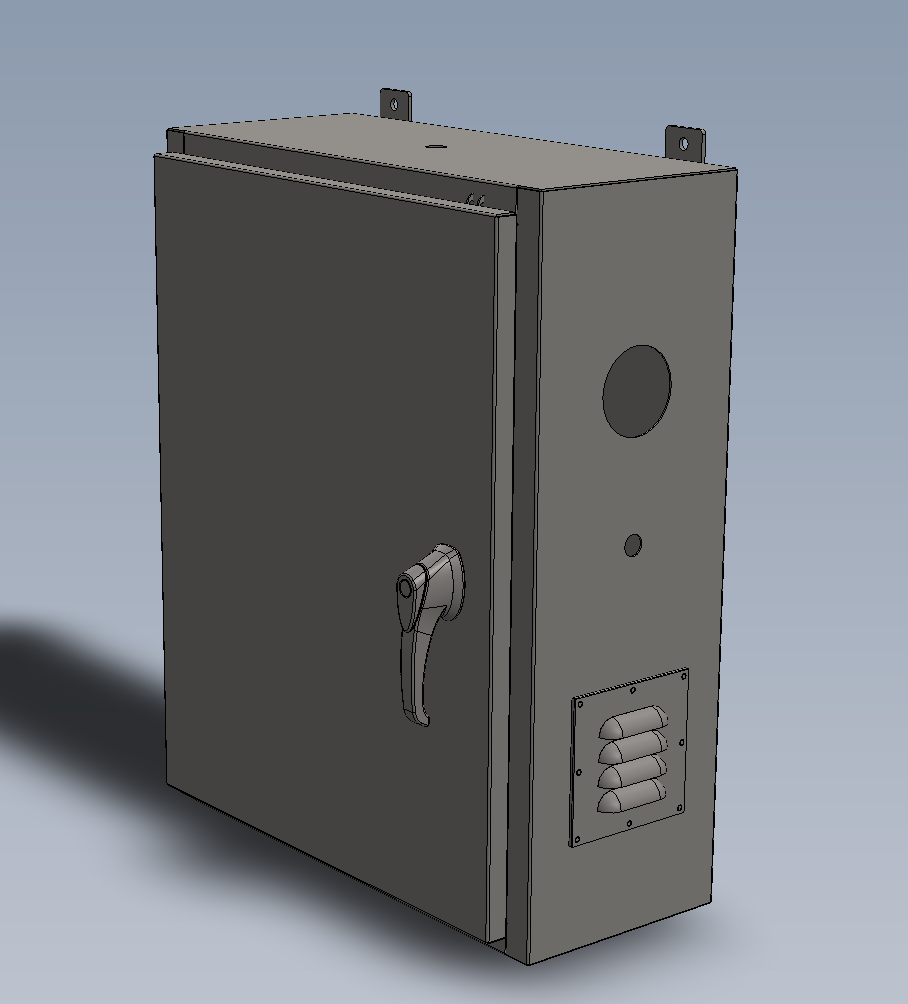

NEMA 3RX Rating Now Offered

Nema Enclosures Mfg. is proud to announce that we are now offering NEMA 3RX rated – UL Listed enclosures. These enclosures offer the same great ingress protection as our 3R enclosures, but with an added level of corrosion protection.

Corrosion is a major problem in nearly every U.S. industry sector, costing an estimated $276 billion per year. Carbon steel is susceptible to natural oxidation (rust) and galvanic corrosion. A wide variety of environmental factors can influence the severity of the corrosion and can be difficult to predict accurately. Temperature, humidity, and sulfur dioxide concentration in the atmosphere can all play a role in the rate of corrosion. Environments near the ocean, such as docks, shipyards, and oil platforms are all at risk for heavy sea salt spray.

Put your corrosion worries at ease by choosing a NEMA 3RX enclosure. Nema Enclosures manufactures NEMA 3RX enclosures out of 5052-H32 aluminum, 304L stainless steel, or 316L stainless steel in a wide variety of different styles to meet your application. These material types offer an inherent degree of protection against corrosive agents such as a salt spray, without the need of an additional coating.

NEMA 3RX enclosures are designed with the same corrosion resistance as NEMA 4X, but since they are not required to be dust tight, louvers and other ventilation options can be added. NEMA 3RX enclosures also have the added benefit of being cheaper than their 4X counterpart.

Type 3RX enclosures are constructed for either indoor or outdoor use to provide a degree of protection to personnel against access to hazardous parts; to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt); to provide a degree of protection with respect to harmful effects on the equipment due to the ingress of water (rain, sleet, snow); that will be undamaged by the external formation of ice on the enclosure that provides an increased level of protection against corrosion.

There are five primary ingress protection tests associated with NEMA 250 Type 3RX enclosures:

- Access to hazardous parts

- Ingress of solid foreign objects (falling dirt)

- Ingress of water (dripping and light splashing)

- Ingress of water (rain, snow, and sleet)

- Corrosive agents

Common applications for these enclosures include:

- Power distribution

- Telecommunications

- Junction boxes

- HVAC equipment

- Farm equipment

- Meter Cabinets

- Utility boxes

NEMA 3RX enclosures provide an economical choice for an outdoor application that requires corrosion protection. Please contact us today at 713-921-2233 or by filling out the web form to speak with an expert. We can help you chose a quality NEMA rated enclosure with customizations specific to you and at a fair price.

Posted in enclosures

Comments Off on NEMA 3RX Rating Now Offered

NEMA ENCLOSURES MFG. RECEIVES ISO 9001:2015 CERTIFICATION

For the most part, it is universally accepted that when sourcing and placing your trust in a supplier for any industry that the main focus is usually on price, quality, and overall service. A common mistake is focusing on pricing alone but getting the better price does not always translate to getting the better deal.

We, at Nema Enclosures, embrace the concept of quality through continual improvement, which is why we are proud to announce that our Quality Management System has achieved certification to the new ISO 9001:2015 standard.

Our successful certification is a testament to the positive engagement of colleagues at all levels, and demonstrates our commitment to embrace the standard as a fundamental element of continual improvement, quality and customer focus strategies.

We can ensure we are able to meet the needs of not only our existing customers but also all new and future prospective customers by delivering exceptional enclosures built to your specification.

ISO 9001 is the most widely used quality management standard and has recently undergone a periodic update to better reflect modern business challenges. It’s a symbol that everyone — our customers, our employees, our suppliers — recognizes and values. Last modified in 2008, the new 2015 version of ISO 9001 is the result of input from business and technical experts around the world. The program requires greater involvement of senior management, broader understanding of supply chains, and more focus on stakeholder (not just customer) expectations.

We have developed and implemented our Quality Management System in order to maintain a high level of quality and responsive customer service, improve overall performance and efficiency, and to provide a firm foundation in our approach to continual improvement initiatives for technology, design, and processes and procedures. The decision to adopt and implement the requirements of ISO 9001 and achieve accreditation through an independent third party certification body demonstrates Nema Enclosures’ dedication to providing high-quality and consistent products and services to our customers.

To become certified to the ISO 9001:2015 standard, Nema Enclosures underwent a demanding certification and audit process that included development of the quality management system, documentation review, internal audits, and finally the comprehensive certification audit by DNV GL.

We at Nema Enclosures would like to extend our sincere thanks and appreciation to all of our employees for their efforts in achieving this goal; this would not be possible without a strong team effort, and we are very proud and grateful to all of our employees who made this happen. We would also like to take this opportunity to thank our customers and suppliers for their continued loyalty and commitment, and we will always strive to exceed all of your requirements. We recognize that while this achievement is an important milestone for Nema Enclosures, our work is not done yet. With our focus on quality assurance and continual improvement, we look forward to raising our organization to new heights in the years to come.

About DNV GL – Business Assurance

DNV GL – Business Assurance is part of the DNV GL Group, a world-leading certification body helping businesses assure the performance of their organizations, products, people, facilities and supply chains through certification, verification, assessment, and training services.

For more information about DNV GL – Business Assurance, visit www.dnvglcert.com.

Posted in enclosures

Comments Off on NEMA ENCLOSURES MFG. RECEIVES ISO 9001:2015 CERTIFICATION