Custom VFD Enclosure Manufacturer

Keeping Us Safe Around Industrial Electric Motors

Companies in the VSD/VFD industry are involved in the application, technology, marketing and management of variable speed drives (VSD), variable frequency drives (VFD) and industrial motor driven machinery. A drive is considered to be industrial electrical equipment and therefore, is not meant for private or residential application.

Drives provide a means of continuously regulating the speed of AC inductive motors. To that end, a supply voltage of a particular frequency and amplitude is converted by an inverter into a 3 phase AC voltage of variable amplitude and adjustable frequency. This frequency modulated voltage is then used mostly to regulate the speed of AC asynchronous motors.

The industry is heavily involved in a wide range of safety oriented activities including the testing, certification and approval of electrical equipment. For the most part, safety related product aspects regulate the installation of electrical equipment with the underlying premise being the safety and health of direct users cannot be compromised and endangered by the manner in which the equipment is meant to be operated, nor should any anticipated misuse of the product be overlooked in its design and in the ultimate use for which it is intended.

The basis of safety standards with respect to electrical equipment is safeguarding against potential life threatening dangers such as:

- Electrical shocks involving exposure to dangerous voltage levels,

- Fires resulting from abnormally high temperatures,

- Bodily injuries related to moving parts, sharp edges, unstable assemblies, hot surfaces,

- Chemical hazards emanating from unintended release of health injurious materials

- Exposure to radiation

Therefore, the safety standards see to it that established engineering principles and sound protective requirements are put in place to safeguard against these potential hazards.

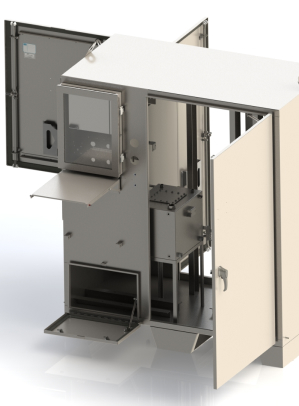

Nema Enclosures creates reliable carbon steel enclosures for variable speed drive and variable frequency drive applications. The key feature of these VSD and VFD enclosures is their capability to manage heat buildup effectively. The accumulation of heat in any enclosure can damage the electrical and electronic components inside. Overheating can shorten the life expectancy of these components or lead to performance failure.

Special thermal management solutions incorporated in VSD and VFD enclosures include:

- Rear panel access for heat sinks that transfer heat effectively away from the enclosure’s electronic components,

- Custom cutouts for circulating fans and blowers for air circulation and ventilation as well as heat exchangers and air conditioners for closed loop cooling,

- Louver covers to control cool air movement throughout the enclosure,

- Pre-punched louvers to facilitate heat dissipation in the enclosure and the effective cooling of drivers,

- Sun shields for economical reduction of solar heat gain in outdoor electrical enclosures.

Types of electrical enclosures used with VSD/VFD applications:

Specifying the electrical enclosure should not be the last thing you think about.

Nema Enclosures fabricates quality safety rated powder coated carbon steel, stainless steel and aluminum electrical and instrument enclosures to your exact specifications and that meet your lead times. We believe that by thinking about your enclosure needs while you’re configuring what goes into it will save you time, money and frustration.

Our standard enclosures are available in wall-mount, free standing, floor mount, junction box and trough types – depending on what fits your needs best. All electrical enclosures are manufactured in compliance with NEMA standards; are UL listed, and/or IP rated. Nema Enclosures electrical enclosures adhere to strict Nema Enclosures Quality Standards to ensure product performance and reliability.

Contact us today to learn how we can expedite custom VFD and VSD enclosures and produce cost-effective safety rated standard enclosures to protect you and your equipment.

Contact Us