Offshore Oil & Gas Enclosures

A Traditional Industry Embracing New Technology

Worldwide demand for oil and gas continues to increase to meet the needs of developing markets. New exploration continues as old oil and gas fields are depleted requiring increased drilling, production, storage, and distribution services. The desire for faster and more efficient production has dramatically increased the demand for cutting-edge electronic control systems and processes - coupled with the need for safety in highly flammable gas and liquid environments.

The oil and gas industry consists of three groups:

- Upstream: searching for potential underground or underwater crude oil and natural gas fields, drilling exploratory wells, and drilling the operating wells that recover and bring the crude oil and/or raw natural gas to the surface.

- Midstream: transportation, storage, and marketing of the various oil and gas products produced by processing plants and refineries.

- Downstream: refining of petroleum crude oil, processing and purifying of raw natural gas, marketing and distribution of products derived from crude oil and natural gas including gasoline, kerosene, jet fuel, diesel oil, heating oil, fuel oils, lubricants, waxes, asphalt, natural gas, and liquefied petroleum gas (LPG).

As these industry sectors have become more sophisticated and specialized, the processing systems have also continued to require increasing computational power and communications bandwidths. These systems produce significantly higher levels of heat than previous systems and as a result, are more sensitive to harsh environmental factors. Typically these electrical/electronic systems are installed in sealed enclosures making thermal overrun temperatures one of the leading causes of failure and reduction in MTBF. The removal of heat generated by these advanced electronics systems has grown to be a critical issue since these systems must often perform in high ambient temperature environments.

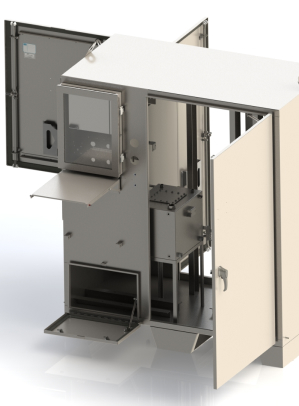

Many enclosures in this industry need to be suitable for hazardous locations. We can provide NEMA enclosures for offshore applications rated for Class I Division II environments where a purge system is used. Nema Enclosures can provide the proper cutouts for the purge controller, breather, and drainer typically required in these applications.

Oil and gas producers depend on durable, reliable control systems to manage their operations effectively, offshore and on. NEMA enclosures for offshore applications are rigorously tested daily in extreme environmental conditions that would overwhelm any standard product.

Nema Enclosures designs and manufactures electrical enclosures for the oil and gas industry that cater to downhole applications and drilling technology integration, in some applications listed below:

- Top Drive Enclosures

- Dog House Enclosures

- CIP Panels

- HMI Enclosures

- Frac and Remote Frac Control Enclosures

Nema Enclosures offers electrical enclosure solutions for offshore applications that exceed these severe product demands head-on:

- Tamper-resistant features

- Safety rated to meet or exceed the NEMA 4X standards

- Wide range of available hazardous-environment accessories including:

- Window kits

- Hole seals

- Vent drains

- Lights and purge controllers

- Cutouts for touch screens

- Heavy-duty plinth bases for high wind locations.

- Specialized powder coatings to protect in highly corrosive areas

- Sun and weather shields to protect against heat and UV exposure

- Temperature-control options

Types of electrical enclosures used in the oil and gas industry:

- Wall Mount

- Junction Box

- Floor Mount

- Free Standing

- Trough

- Custom – design from components and required spacing to a completed enclosure for field installation

Specifying the electrical enclosure should not be the last thing you think about.

Nema Enclosures fabricates quality safety rated powder coated carbon steel, stainless steel and aluminum electrical and instrument enclosures to your exact specifications and that meet your lead times. We believe that by thinking about your enclosure needs while you’re configuring what goes into it will save you time, money and frustration.

OOur standard enclosures are available in wall-mount, free standing, floor mount, junction box and trough types – depending on what fits your needs best. All electrical enclosures are manufactured in compliance with NEMA standards; are UL listed, and/or IP rated. Nema Enclosures electrical enclosures adhere to strict Nema Enclosures Quality Standards to ensure product performance and reliability.

Contact us today to learn how we can expedite custom enclosures and produce cost-effective safety rated standard enclosures to protect you and your equipment.

Contact Us