-

Recent Posts

- Nema Enclosures Mfg. awarded ISO 9001:2015 re-certification as a Seal of Quality Standard

- NEMA 3RX Rating Now Offered

- NEMA ENCLOSURES MFG. RECEIVES ISO 9001:2015 CERTIFICATION

- Learn about our ATEX & IECEx Ex e Value Added Features and Accessories

- Motor Control Center (MCC) Drop-Over Custom Enclosures

Archives

- May 2021

- February 2021

- July 2018

- October 2017

- September 2017

- April 2017

- January 2017

- December 2016

- March 2016

- February 2016

- October 2015

- August 2015

- July 2015

- May 2015

- October 2014

- August 2014

- June 2014

- April 2014

- March 2014

- February 2014

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- February 2013

- January 2013

- December 2012

- November 2012

- October 2012

- September 2012

- March 2012

- February 2012

- August 2011

- May 2011

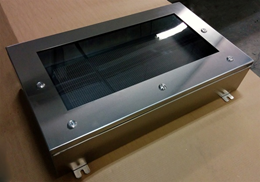

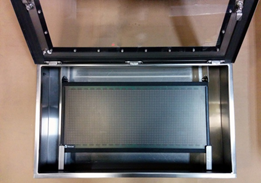

Nema Enclosures for Vorne Productivity Appliances

Food Processors! Nema Enclosures NEMA 4X hose down rated 316L stainless steel enclosures protect Vorne Productivity Appliances™ during washdown.

Nema Enclosures protects your Vorne Productivity Appliance investment. We wrap your sensitive technology in a hose down rated 316L stainless steel enclosure designed to keep the elements out while keeping what’s important inside safe – ensuring that you continue to receive the critical actionable information you need when you need it.

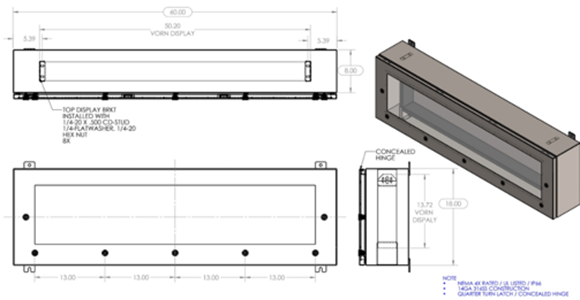

Our enclosures feature a shatterproof window, sealed door, quarter turn latches and concealed hinges.

It’s easy to mount anywhere in your facility.

NEMA 4X hose down rated enclosures

NEMA 4 hose down rated enclosures are constructed for either indoor or outdoor use to provide a degree of protection to personnel against access to hazardous parts; to provide a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt and windblown dust); to provide a degree of protection with respect to harmful effects on the equipment due to the ingress of water (rain, sleet, snow, splashing water, and hose directed water); and that will be undamaged by the external formation of ice on the enclosure. NEMA 4X rated enclosures are constructed with all of the protection of the NEMA 4 rating plus protection against corrosion of the enclosure.

Vorne Productivity Appliances provide an economical way to gather actionable information that expose production problem areas fast.

Vorne Productivity Appliance in wall mounted Nema Enclosures 4 | 4X hose down rated stainless steel enclosures.

Vorne Productivity Appliances also provide a way to inspire and motivate the people that have the greatest impact on productivity – plant floor employees.

The Vorne Productivity Appliance is a “bolt-on” performance management tool that is so easy to use that it can be self-deployed in about an hour. It automatically tracks production in real-time and instantly delivers meaningful, accurate, and actionable information anywhere in the world. The integrated large area visual display informs, alerts, and motivates plant floor employees, while the built-in Ethernet LAN connection delivers instant production reports and analytics to supervisors and managers.

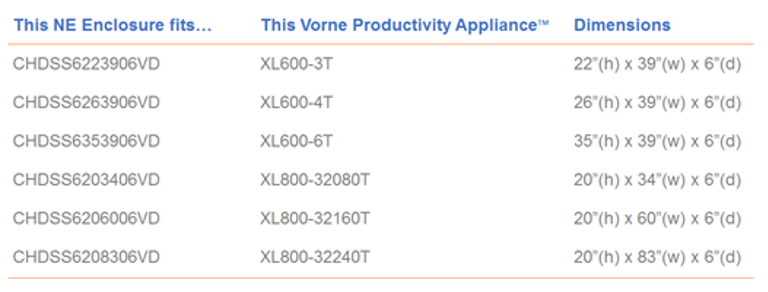

There’s a hose down rated Nema Enclosures enclosure designed for every Vorne Productivity Appliance.

They’re easy to order. Simply use the chart below to match your enclosure product number to your productivity appliance model number when ordering.

A drawing of a wall mounted Nema Enclosures 4X hose down rated 316L stainless steel enclosure for a Vorne Productivity Appliance.

Protect your Vorne Productivity Appliances during wash down in Nema Enclosures hose down rated 316L stainless steel enclosures.

Posted in enclosures

Comments Off on Nema Enclosures for Vorne Productivity Appliances

Nema Rating Buying Guide

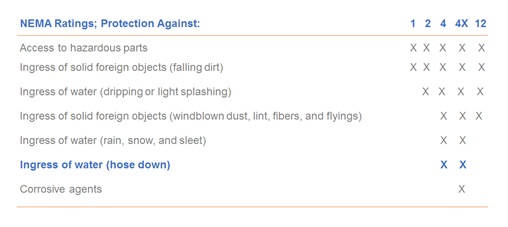

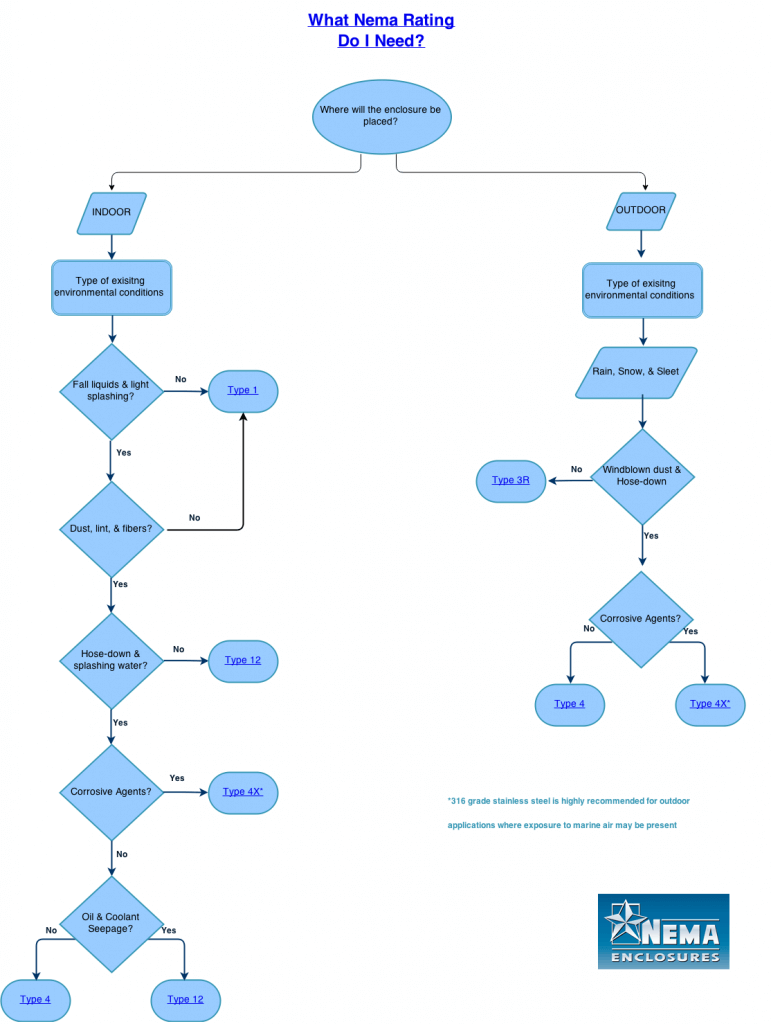

NEMA is a rating system for equipment that might be exposed to liquids, rain, ice, corrosion and contaminates such as dust.

If unsure of the enclosure rating that is required of your project, please refer to the design chart below. The chart will assist in specifying which enclosure rating is appropriate for the environment and application needed.

For in depth information on the different Nema ratings we offer, please continue reading to the list below.

Type 1: General purpose enclosures constructed for indoor use. Protects against dust, light, and indirect splashing but is not dust-tight. Primarily prevents incidental contact with the enclosure equipment. We adhere to NEMA standards to provide you a quality enclosure for most basic applications.

Type 3R: Intended for outdoor use. Provides a degree of protection against falling rain and ice formation. Constructed (with knockouts on the sides and bottom) to prevent beating rain from interfering with the successful operation of the apparatus or result in wetting of live parts and wiring within the enclosure under specified conditions. Please be aware that these are not rain-tight, which means exposure to beating rain could result in water entering a Type 3R enclosure under certain conditions; nor are they water-tight, which means moisture could enter a Type 3R enclosure when subjected to a stream of water under certain conditions. This style of enclosure does not have a gasketed sealing surface. Nema Enclosures manufactures NEMA 3R enclosures for housing power distribution, lighting contractors, switch gear, and other electrical components that need to be protected in an outdoor environment. Our adherence to UL 508A standards will give you a quality weatherproof enclosure resistant to rain, ice, and snow

Type 4: Weather tight (weatherproof) enclosures. Constructed for either indoor or outdoor use to provide a degree of protection against falling dirt, rain, sleet, snow, windblown dust, splashing water, and hose-directed water. Will be undamaged by the external formation of ice on the enclosure. NEMA 4X is used when protection from the worst environments is required. Our NEMA 4 enclosures come in powder coated carbon steel and are available in a variety of types, such as wall-mounted, free-standing and JIC. Nema Enclosures strictly adheres to the exacting NEMA standards in order to provide you a quality electrical enclosure at competitive price.

Type 4X: Same as Type 4 except constructed from corrosion-resistant material. Corrosion-resistant as defined by industry standards is: Constructed to provide a degree of protection against exposure to corrosive agents such as salt spray. Nema Enclosures produces these enclosures in 5052-H32 aluminum, 304/304L stainless steel, or 316/316L stainless steel and they are available in a number of styles for your demanding applications.

Stainless steel is the strongest of the corrosion resistant materials. It exhibits many of the same resistances attributed to fiberglass materials as well as resistance to highly polar solvents such as acetone and MEK.

316 grade stainless steel is the strongest of the corrosion resistant materials that provide improved resistance to salt, some acids, and high temperature. 316 grade is a strongly recommended choice for marine environments which are within 5 miles of salt water or otherwise subject to salt spray. Note that 316 grade resistance to sulfates and chlorine is less than that provided by 304 grade.

Cautionary aesthetic note: Stainless steel of any type is not “stain-free”, and while it offers a high degree of performance, under certain environmental conditions it remains susceptible to rust deposits on the surface. These deposits are often created by contamination resulting from rain or marine environments. Periodic cleaning of the surfaces of stainless steel enclosures with a neutral solution is recommended to avoid “tea staining” Regular washing with clean, fresh water or even rain water has a significant effect on reducing the incidence of tea staining.

Type 12: Constructed (without knockouts) for indoor use to provide a degree of protection to personnel against access to hazardous parts. Provides a degree of protection of the equipment inside the enclosure against ingress of solid foreign objects (falling dirt and circulating dust, lint, fibers, and fyings). Also provides a degree of protection with respect to harmful effects on the equipment due to the ingress of water (dripping and light splashing). Gasketed doors seal the enclosure’s contents from airborne contaminants and non-pressurized water and oil. Nema Enclosures produce NEMA 12 enclosures which are intended mainly for indoor industrial, manufacturing, and machining applications. We produce a number of enclosure types in aluminum, carbon steel and stainless steel delivered quickly at competitive prices.

Posted in enclosures

Comments Off on Nema Rating Buying Guide

Difference in Properties & Yield Strength Between 5052 vs 6061

Aluminum alloys are excellent for electrical enclosures that are designed for use in harsh, high heat, high wear conditions typically found in water and wastewater treatment plants. Aluminum alloys are also gentle on the environment.

Aluminum NEMA rated enclosures offer a combination of strength, light weight and corrosion resistance.

Sheet of aluminum Custom aluminum enclosures

Pure aluminum has a high tensile strength. This strength is substantially increased when alloyed with manganese, silicon, copper, magnesium or zinc.

In addition to its strength; attractive finish and an ability to undergo the anodizing process are also great qualities of aluminum.

Aluminum alloys have higher thermal conductivity relative to other electrical enclosure materials, therefore providing superior high heat dissipation.

Many aluminum alloys are heat treatable. Heat treating can alter the mechanical properties of the alloy by manipulating its properties such as the hardness, strength, toughness, ductility, and elasticity.

Aluminum is recyclable with nearly 75% of all aluminum ever produced since 1888 still in use today. Recycling aluminum uses 95% less energy and produces 95% less greenhouse gas emissions than producing metal from new materials.

Aluminum is less expensive than stainless steel, especially when compared to 316 stainless steel.

Aluminum is more durable than carbon and stainless steel.

The superior corrosion resistance quality of aluminum makes it a superior metal for use in industries such water management and wastewater treatment. The reason aluminum resists corrosion so effectively lies in its ability to spontaneously form an oxide layer to prevent further oxidation. Aluminum oxide is impermeable and strongly adheres to its parent metal – unlike the oxides of many other metals. Plus, the aluminum oxide layer will repair itself if damaged.

The layer is stable in the general pH range 4-9.

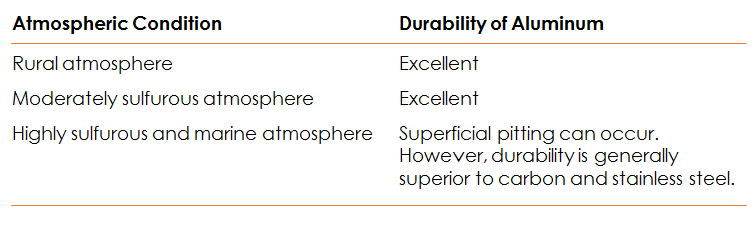

The chart below shows the relative durability of aluminum in various environmental conditions.

Chart 1: Durability of aluminum in various atmospheric conditions

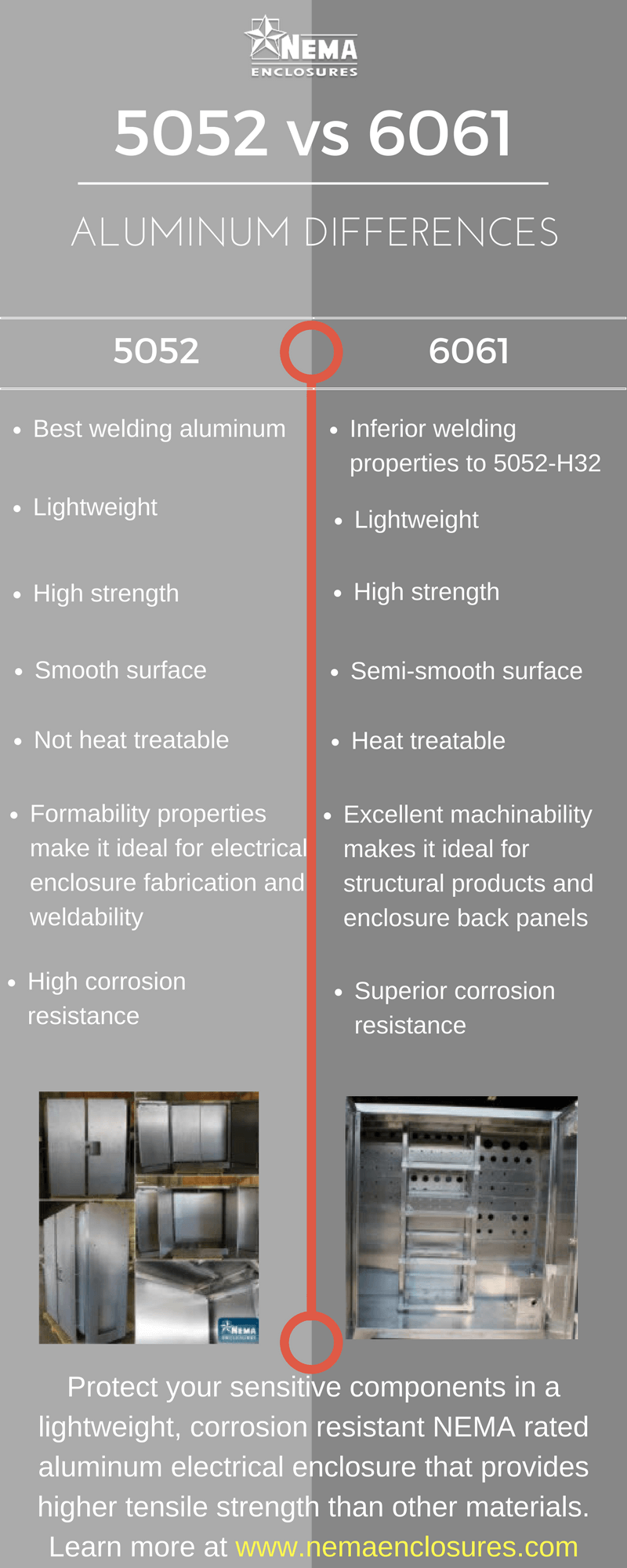

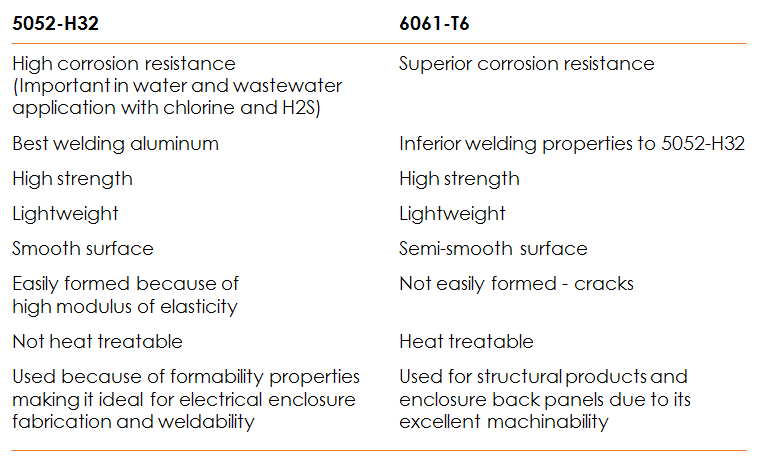

5052-H32 aluminum alloy or 6061-T6 aluminum alloy for your NEMA rated electrical enclosure – which one is better for you?

The answer is quite simple – only 5052-H32 has the properties suitable for the fabrication of formed electrical enclosures. Let’s compare the two alloys to see why.

Chart 2: Comparison of 5052-H32 and 6061-T6 properties

5052-H32 is optimal for sheet metal work because of its ability to allow for a tight radius while bending.

5052-H32 contains 2.5% magnesium. It is one of the highest strength alloys of the non-heat treatable grades. Common uses for this alloy include the manufacturing of electrical enclosures, marine parts, home appliances, food equipment, fuel tanks, storm shutters, refrigerators, aircraft tube, and fences.

6061-T3 is not recommended for sheet metal work because it will crack on the outside radius once it passes its yield when being processed on a brake press, for example.

6061-T6 is the most commonly used aluminum alloys. The main alloy ingredients are magnesium and silicon. Common uses for this alloy are in the manufacturing of fishing reels, truck frames, structural components, machine parts, aircraft and aerospace components, marine fittings, camera lenses, transport, valves, and couplings.

Both alloys can undergo the anodizing process to increase corrosion resistance and enable dying (coloring). The anodic layer is non-conductive.

5052 is generally less expensive than 6061.

In summary, certain aluminum alloys (especially 5052-H32) are excellent materials for NEMA rated electrical enclosures – especially if your enclosure is going to be used outdoors and/or heat dissipation is a consideration.

Posted in enclosures

Comments Off on Difference in Properties & Yield Strength Between 5052 vs 6061