-

Recent Posts

- Nema Enclosures Mfg. awarded ISO 9001:2015 re-certification as a Seal of Quality Standard

- NEMA 3RX Rating Now Offered

- NEMA ENCLOSURES MFG. RECEIVES ISO 9001:2015 CERTIFICATION

- Learn about our ATEX & IECEx Ex e Value Added Features and Accessories

- Motor Control Center (MCC) Drop-Over Custom Enclosures

Archives

- May 2021

- February 2021

- July 2018

- October 2017

- September 2017

- April 2017

- January 2017

- December 2016

- March 2016

- February 2016

- October 2015

- August 2015

- July 2015

- May 2015

- October 2014

- August 2014

- June 2014

- April 2014

- March 2014

- February 2014

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- February 2013

- January 2013

- December 2012

- November 2012

- October 2012

- September 2012

- March 2012

- February 2012

- August 2011

- May 2011

DESIGNABOX® Ends Electrical Enclosure Cut Out Frustration

When it comes to customizing electrical enclosure cut outs there’s the way many control panel manufacturers do it today and there’s a new way that’s faster and easier.

The way a lot of control panel manufacturers customize enclosure cut outs today…

- After buying an electrical enclosure that sort of meets their specs,

- Customization starts by measuring the cut outs by hand – usually with inaccurate measurement tools,

- Measurements are masked with tape to protect the enclosure finish,

- Corner guide holes are drilled – hopefully, not too many drill bits are worn out,

- Cuts are made with a jig saw – which often ends up with a bent saw blade,

- Once the cut out is finished, the tape is removed,

- The edges and corners are filed and finished.

That’s a lot of expensive, time consuming work with additional costs for labor and materials. It doesn’t have to be this way.

Now there’s a better way. You can customize your enclosure exactly the way you need it before you buy it online using DESIGNABOX® enclosure design software.

The new registered trademark of the DESIGNABOX® online retail store.

The DESIGNABOX® online ecommerce landing page.

When it comes to electrical enclosure cut outs, DESIGNABOX® frees you from; measuring your cut out by hand, masking, drilling, cutting, and filing.

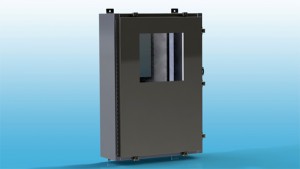

All you do is order the enclosure size, type, material and rating you need, customize it and buy it. It’s all done online and ready for manufacturing. Lead times are shortened to as little as 5 days for a custom product with NO minimums.

It’s that simple.

Your DESIGNABOX® customized enclosure drawing rendered online in real time.

DESIGNABOX technology enables control panel manufacturers to do what you do best and virtually eliminates human error in electrical enclosure cut outs.

DESIGNABOX enables you to quickly and easily do the following:

- Customize your electrical enclosure exactly the way you need it before you buy it.

- Choose your electrical enclosure in the size, material and rating you need,

- Design your cutouts and accessories to your exact specifications online,

- Conveniently order and purchase your enclosure.

Your design is seamlessly integrated into our ISO certified manufacturing process to minimize human error so you receive your enclosure ready for use exactly the way you designed it.

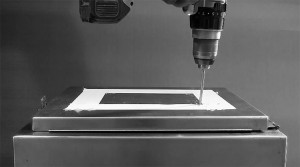

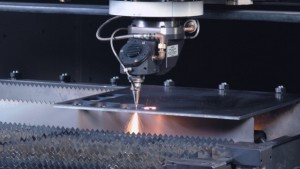

A laser makes precise cut outs in seconds.

You get precise electrical enclosure cut outs and no more added hours of work, wear and tear on shop tools, dull drill bits, bent saw blades, and frustration.

Electrical enclosures ordered online at https://www.nemaenclosures.com/custom-enclosures.html meet these industry standards.

![]()

Find out more at: https://www.nemaenclosures.com/custom-enclosures.html

This entry was posted in enclosures. Bookmark the permalink.