-

Recent Posts

- Nema Enclosures Mfg. awarded ISO 9001:2015 re-certification as a Seal of Quality Standard

- NEMA 3RX Rating Now Offered

- NEMA ENCLOSURES MFG. RECEIVES ISO 9001:2015 CERTIFICATION

- Learn about our ATEX & IECEx Ex e Value Added Features and Accessories

- Motor Control Center (MCC) Drop-Over Custom Enclosures

Archives

- May 2021

- February 2021

- July 2018

- October 2017

- September 2017

- April 2017

- January 2017

- December 2016

- March 2016

- February 2016

- October 2015

- August 2015

- July 2015

- May 2015

- October 2014

- August 2014

- June 2014

- April 2014

- March 2014

- February 2014

- September 2013

- August 2013

- July 2013

- June 2013

- May 2013

- April 2013

- February 2013

- January 2013

- December 2012

- November 2012

- October 2012

- September 2012

- March 2012

- February 2012

- August 2011

- May 2011

ISO 9001:2008 Scope of Certification

Our quality management system governing the manufacture of our electrical enclosures is now ISO 9001:2008 certified.

Perry Johnson Registrars, Inc. has audited the Quality Management System of Nema Enclosures Manufacturing of Texas, LLC and declares that we are in conformance with ISO9001:2008 standards for the manufacturing of custom metal enclosures fabricated to customer specification.

This means we demonstrate the ability to consistently provide product that meets customer and applicable statutory and regulatory requirements and that we aim to enhance customer satisfaction through the effective application of our system, including processes for continual improvement of the system and the assurance of conformity to customer and applicable statutory and regulatory requirements.

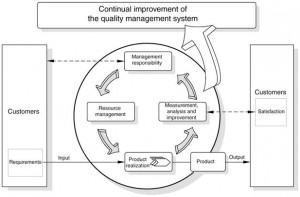

International Organization for Standardization (ISO) Process Approach

According to the International Organization for Standardization (ISO),

“This International Standard promotes the adoption of a process approach when developing, implementing and improving the effectiveness of a quality management system, to enhance customer satisfaction by meeting customer requirements.

For an organization to function effectively, it has to determine and manage numerous linked activities. An activity or set of activities using resources, and managed in order to enable the transformation of inputs into outputs, can be considered as a process. Often the output from one process directly forms the input to the next.

The application of a system of processes within an organization, together with the identification and interactions of these processes, and their management to produce the desired outcome, can be referred to as the “process approach”.

An advantage of the process approach is the ongoing control that it provides over the linkage between the individual processes within the system of processes, as well as over their combination and interaction.

When used within a quality management system, such an approach emphasizes the importance of:

- a) Understanding and meeting requirements,

- b) The need to consider processes in terms of added value,

- c) Obtaining results of process performance and effectiveness, and

- d) Continual improvement of processes based on objective measurement.

The model of a process-based quality management system shown in Figure 1 illustrates the process linkages presented in Clauses 4 to 8 of the standard. This illustration shows that customers play a significant role in defining requirements as inputs. Monitoring of customer satisfaction requires the evaluation of information relating to customer perception as to whether the organization has met the customer requirements.

The model shown in Figure 1 covers all the requirements of this International Standard, but does not show processes at a detailed level.”

We received certification on September 22, 2014.

For more information regarding the ISO9001:2008 scope of certification, visit www.iso.org.

This entry was posted in enclosures. Bookmark the permalink.